In Stock Equipment - New CNCs and Robots

All items below are in stock at our Flesherton, ON location. We also have access to Absolute Machine Tools US based stock, they typically have over 100 machines available. Request a quote for us for any of their in stock items.

Travels

Longitudinal Travel (X) Axis:27.6"

Cross Travel (Y) Axis:16.5"

Vertical Travel (Z) Axis:11.8" (16.9” for KT-420AL)

Table to Spindle:6.7" min/18.5" max (23.6” max for KT-420AL)

Spindle Center to Column:18.9"

Table

Table Working Surface:31.5" x 15.7"

Maximum Workload on Table:660 LBS.

Table Surface:Ground / T-slotted

No. of T-slots x Width:3 x 14mm

Table height from floor:34”

Spindle (Standard)

Spindle Motor:28HP peak / 6.5 HP continuous

Spindle Taper:BBT-30 dual contact

Spindle Drive System:Direct Drive

Spindle Speed:0-15000 RPM

Automatic Tool Changer – Turret Type (Standard for KT-420L)

Number of Tools:21 tools

Tool Selection:Bi-directional-fixed

Tool Change Time:1.07 sec tool to tool

Chip to Chip Time:1.36 sec chip to chip

Magazine Index Time Adjacent Station:0.1 seconds

Magazine Index Time 180 degrees:1.8 seconds

Maximum Tool Diameter:3.94"

Maximum Tool Weight:6.6 LBS

Tool Type:BBT-30

Maximum Tool Length:7.9"

Ballscrews and Axis Motors

X-Y-Z Ballscrew Diameter: X 36mm (1.42”) x 16mm pitch, Y 28mm (1.1”) x 16mm, Z 32mm (1.25”) x 20mm

Ballscrew Type:Class 3 double nut pre-loaded

Ballscrew Mounting Type: Double anchored

X-Y-Z Servo Motor HP : 2.0 – 2.0 – 3.0HP

Servo Motor Mounting: Direct coupled

Feeds

Rapid Traverse Rate X,Y,Z: 1969, 1969, 2362 IPM

Acceleration in Z: 1.0G

Cutting Feed Rate: 0.01 - 787 IPM

Positioning Accuracy: +/- .0002” full stroke

Repeatability:+/- .00015"

General

Coolant Tank Capacity : 60 gallons

Machine Weight: 5,720 LBS

Floor Space (without optional chip conveyor): 81" x 99" x 105"

Machine Power Source: 208/220 Volts, 3 Phase 40 Amps**

Air Source:90 PSI

| |

| |

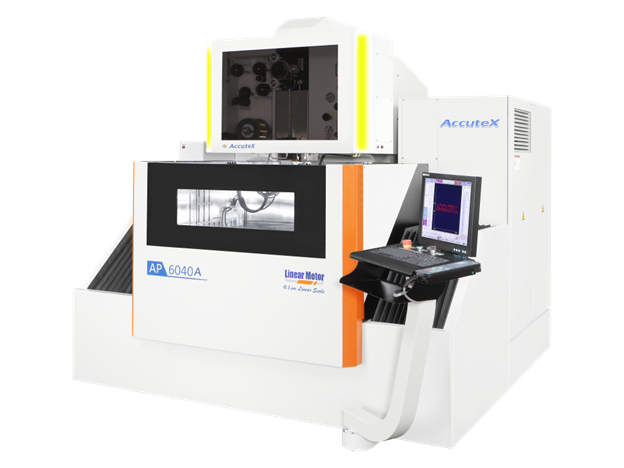

AccuteX Linear Shaft Motor X,Y

High Speed Digital/AC Power Supply

64 Bit Windows CE Based CNC Control

Fagor Linear Glass Scales

Fully Closed Loop 0.000004” Resolution

45° Taper Cutting Capability (wide angle guides and flush cups required)

5 Controllable Axes (X, Y, U, V, Z)

Work Coordinate System G54-G959 (60 work points)

Hand-Held Remote Pendant

15” Color Monitor

Extended Life Filtration Unit

Ethernet (standard)

RS 232C Input

Lead In/Out Function (reduces whitness mark)

AWT Monitor Screen

Conversational Cutting Condition Selection with API (automatic program imbedding)

Built in Collision Detection (All Axis)

Chiller Unit (standard)

Inch/Metric Switchable by program

Parametric Macro Sub Programming

Automatic Corner Pro Function

Automatic Wire Feed System (Re-Thread at Break-Point)

Ergonomic CNC Operator Panel (Swivel Mounted and

Adjustable)

Edge Finding/Centering Manually, By G-Codes and by Guidance Menus

On Board Operation and Help Menus

SD Master – Stable Discharge Circuit with EPGA Technology

USB Port

Saftey Door Interlock

| |

| |

| |

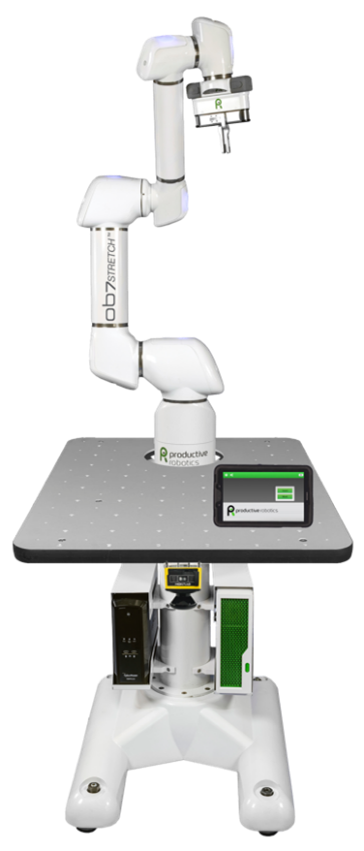

Rolling Robot Stand

Robot Work/Assembly Table

PG2 Parallel Gripper

Electronic Robot Interface includes (8) inputs/outputs controller, regulator, and (2) valves

4” Pneumatic Soft Jaw Air Vise

CleanTech 160mm Chip Fan with ¾ Shank

PG-2 Dual Y Gripper + Adapter

Banner Laser Safety Scanner

Kurt Air Versatile Pneumatic Lock Vise 0-9.25”

Copyright © 2020-2024 CWL Solutions Inc.

All rights reserved.

Calculators

Calculators